Multi-Effect Distillation (MED)

Nowadays, MED evaporator is being frequently used for desalination process.

The system consists of multiple consecutive effects which operate at decreasing pressure and temperature. The first effect will operate at high pressure (HOT) and the last one at the lowest pressure (COLD). [P1>P2>P3…]

Each effect or cells consist of vertical plate bundles.

Sea/Salt water is sprayed on the top of the bundle which then flows down over the plates by gravity. Simultaneously steam is introduced in the plates. Heat Transfer takes place. Steam condenses into distillate & due to evaporation sea/salt water will get concentrated as it flows downwards, and the vapor released which is at lower temperature than steam will be used as the heating medium for the next effect. Flashing takes place in the next effect as it operates at a lower pressure than that of the previous one. Additional amount of vapor is raised which condenses as distillate in the next effect. This process is repeated in several effects.

In the last effect, the vapor/steam is led to a plate type exchanger where it condenses into distillate. The cooling media for this exchanger is the salt/sea water, which in turn warms up to be used as feed in the first effect.

Brine and distillate collected from effect to effect till the last one is extracted by centrifugal pumps.

Thermal efficiency can be defined as number of kilos of distillate produced per number of steam introduced in the system.

This number is known as Gain Output Ratio (GOR).

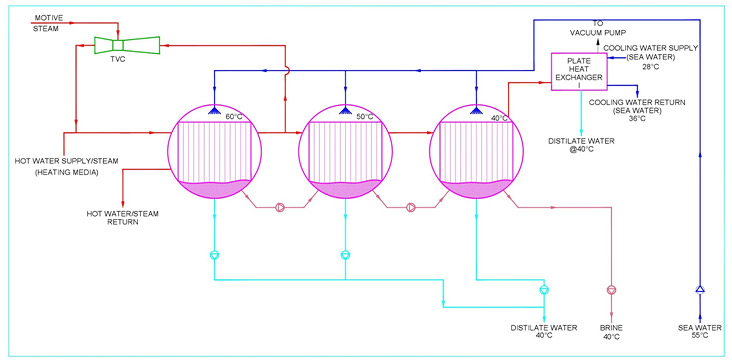

Multi-Effect Distillation with Thermal Vapor Compression (MED-TVC)

The GOR can be increased by installing a thermal vapor compressor between the first effect (hot) and any one of the other effects.

This static TVC will take part of the released vapor from one of the effect and using low or medium steam will convert the vapors into high pressure vapor which in turn will be used as heating media for the first effect. This mechanism can almost double the GOR compared to the simple MED system.

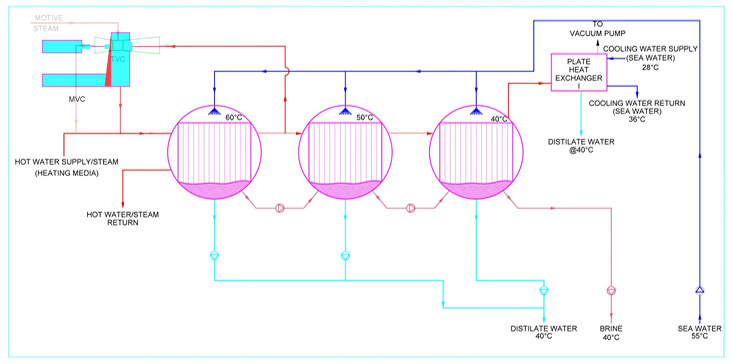

Multi-Effect Distillation with Mechanical Vapor compression (MED-MVC)

In absence of steam, TVC can be substituted by Mechanical Vapor compression which will recycle the vapors from the cold effect to the hot effect by means of a centrifugal compressor driven by electrical engine.

-

Electrical consumption: 9-15 kWH/m3

-

Capacity: 4500-5000 m3/day.

As it is an electrical process, it is environmentally clean and gives high energy efficiency. Sea water consumption is also less as only the make-up (feed) water necessary.

Advantages of MED & MED-TVC:

- Production of high purity distillate

- Avoids corrosion & scaling as it can operate at low temperatures and at lower concentration

- Simplicity in operation and high reliability

- Easy installation (skid mounted) & reduction in civil work costs( reduced foot print)

- Requires minimum supervision even for 24 hr operation along with low maintenance cost.

- It can be coupled with power plants, gives high thermal efficiencies & reduction in fuel cost.

- Steam pressure can range from 0.4 to 40 bar abs.

- No restriction on heat source. Hot water can also be used.

- No Pre-treatment of sea water required. High Tolerance for sea water conditions.

- Gives high range of production (65000 -68000 m3/day)

Characteristics:

- Simplicity in design so easy access to the internals of MED

- Superior quality materials selected along with highly efficient stainless steel wire demisters.

- Water will be sprayed through nozzles or perforated trays, therefore better distribution, no plugging and allows final degassing of sea water.

- It will be factory tested and assembled to reduce installation on site.

- Availability of range of standard MED-TVC & MED-MVC units

Heat / Energy Sources:

- MED

- Very low pressure steam (0.35 bar a )

- Hot water sources above 60ᵒC

- MED-TVC

- Low and medium steam (above 2 bar a)

- MED-MVC

- Electricity